At the start of the COVID-19 pandemic, Boston University’s Design, Automation, Manufacturing, and Prototyping (DAMP) Lab was tasked with creating a diagnostics workflow in three months. DAMPLab’s Lead Lab Specialist Rita Chen created a prototype COVID-19 diagnostics stack using Opentrons in three months.

In a joint webinar with GenomeWeb and Opentrons, she explains how. Here’s the video and the transcript:

NOTE: This transcript is from a GenomeWeb eCase Study in which Rita Chen of the DAMP Lab discussed her experience building a COVID-19 diagnostics workflow using the Opentrons OT-2 liquid handler. The transcript has been lightly edited for clarity and length.

Rita Chen’s skills combine expertise in experimental techniques with lab protocols for robotic automation. Her work has contributed to understanding the translation of wet-lab protocols into high-throughput, repeatable operations.

Rita Chen: When Boston University was shut down in mid-spring 2020 due to the COVID-19 pandemic, the Design, Automation, Manufacturing, and Prototyping (DAMP) Lab was contacted by Professor Catherine Klapperich, the principal investigator of the Precision Diagnostic Center, to think about how Boston University could put together a COVID-19 diagnostics facility within in a three month timeline.

The main aim was to establish a COVID-19 diagnostics facility for the Boston University community so that students, faculty, and staff could resume their regular activities during the fall 2020 academic semester. This objective of the high-throughput diagnostics facility was the testing of up to 6,000 members of the Boston University community every day with a testing turnaround time of 24 hours.

With the objective of 6,000 tests per day, at a 24-hour turnaround time, automation was a crucial component for solving this challenge, but we did not have the robotic infrastructure to support it. In order to demonstrate the importance of automation for this project, a comparative calculation was performed. It found that it would take a person six hours to complete the RNA extraction protocol for each 96-well plate with potential handling errors if someone were to manually perform the protocol, and this was not the best option.

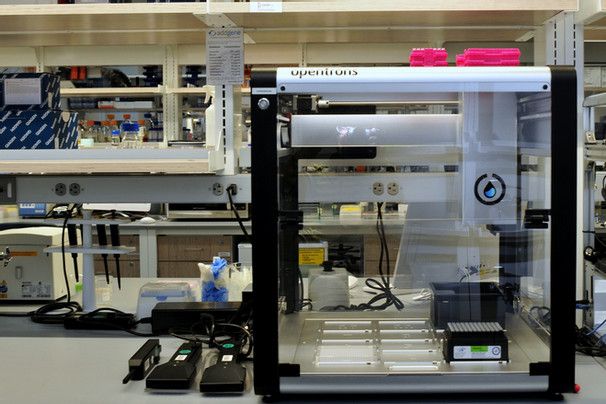

Our obvious first step was to automate this protocol using a liquid handler due to our vast experience using the Opentrons OT-2 liquid handling robot to automate lab protocols for similar purposes. I started our project by prototyping different automation solutions to understand how a Food and Drug Administration-approved COVID-19 protocol could be made reproducible and robust.

To begin resolving the challenge, we decided to prototype the overall automated workflow with the Opentrons OT-2 liquid handling robot, due to its availability and our experience using it for similar challenges. Our first task was to develop an OT-2 script for this specific protocol in the prototyping stage, which could be used to collect preliminary data to show how efficient the liquid handling robot could be.

We started testing the protocol by first implementing an RNA control template, the synthesized RNA products that do not cause the disease. We then created a similar protocol for the inactivated patient samples provided by local hospitals or labs. It is important to know that the scale of the experiment was limited to 96 reactions per day with the single OT-2 system that we had.

The result of the project is a small-scale automated COVID-19 workflow using OT-2 liquid-handling robots and a protocol script that could be implemented by anyone in the world. The open-source protocol script is available to the public at a GitHub repository: https://github.com/DAMPLAB/OT2-SARS-CoV2.

The OT-2 liquid handling robot was very useful to explore this unknown territory. It took half the time to complete the RNA extraction protocol on the 96-well plate using our automated solution in comparison to the manual execution of the protocol. This initial prototyping allowed Boston University’s leadership to make better strategic plans about how we should increase the facility’s scale in a short time frame to allow for a limited return to our campus.

Who else can use what we have built? Anyone with access to an OT-2 and some of the on-deck

modules can use the open-source protocols that are available. The workflow can be broken up into individual biological protocols, such as RNA extraction and qPCR assay preparation. These protocols are some of the most commonly used wet-lab protocols and can be applied to other biological purposes. These materials might also be an excellent introduction to biologists who are new to automation.

I would like to acknowledge the prototyping team: Samuel Oliveira, Lena Landaverde, Luis Ortiz, David McIntyre, and Dany Fu. Thanks to principal investigators Catherine Klapperich and Professor Douglas Densmore from the DAMP Lab.

Additional materials are available on our lab website: http://damplab.org.

If you are particularly interested in the BU COVID-19 diagnostic facility, please visit http://damplab.org/covid-19.

Rita Chen: Of course. The mission of the DAMP Lab is to produce reproducible, standardized, modular, and high-throughput solutions for the community, so our workflows are designed with this mission in mind. Our workflow can be easily modified and broken up into individual biological protocols, so it should be easily modified if a lab wanted to use part of the protocol and not the rest.

Rita Chen: The DAMP Lab is in the process of developing an open-source protocol with the Hamilton Microlab Star liquid handler. However, we’re still in the developmental stage, so we don’t have any material that can be shared at this moment. Eventually, we would like to share everything that we own, and it should be pretty easily accessible, like our current workflow. It should be on GitHub, and it should be made available to the public.

Rita Chen: Well, our lab is a semi-automated cloud-based lab in the sense that we have a laboratory information management system (LIMS). It’s called Aquarium and it manages all related experimental data and results and provides interactive manual protocol steps for the lab technician. Aquarium is open-source software developed by the [Eric] Klavins Lab at the University of Washington. If anyone is interested, you should reach out to the Klavins Lab. They are pretty willing to share their material as it’s open source, and it’s interactive, and it stores all the information you need. If anyone wanted to use a standardized protocol, but not in an automated fashion, you can check out Aquarium as an alternative method.